Mounting example type 2 - Mounting on gateposts with side located door hinges

I. Check material and tool list

Your garden gate closer is delivered already assembled. Your product also includes two aluminium brackets with different side lengths, 4 tapping screws and 2 cap nuts.

WARNING: The garden gate closer is preloaded! The preloading safety should not be removed before insertion! Due to preloading the threaded rods of the gate closer are skewed. They will adjust during assembly.

- 1 garden gate closer

- 1 aluminium bracket (bracket 1): 60, 90 or 120 mm

- 1 aluminium bracket (bracket 2): 30 mm

- 2 cap nuts M6

- 4 tapping screws 4,8 x 19 mm

You will need a cordless screwdriver with a 4.2 mm metal drill and a cross slot (Phillips) screwdriver (PH2) for installation. Furthermore, you need a spirit level, measuring tape, pen and two no.10 fork wrenches.

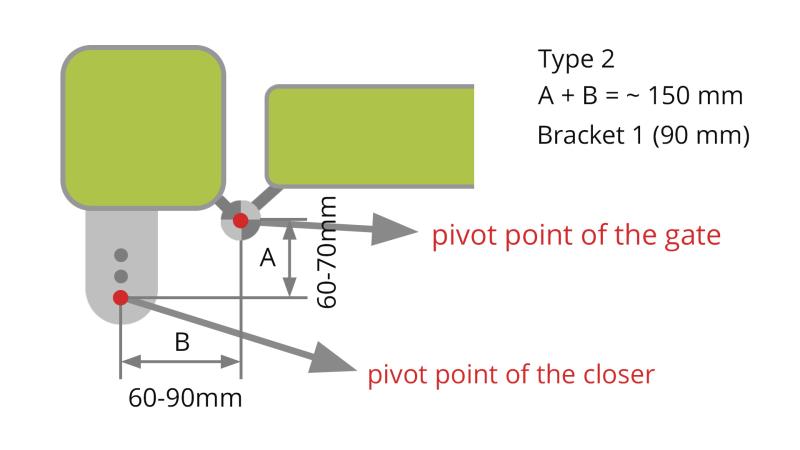

II. Determine type of mounting

The following mounting example shows mounting type 2, that is the mounting on gates with gateposts and with one-sided located door hinges. In this variant you should use bracket 1 with size 90 mm. For different situations, you may eventually need a shorter (60 mm) or longer (120 mm) bracket. All available mounting brackets can be found in the category Accessories.

III. 6 steps for successful mounting

- Determine mounting position of gate closer

- Measure bracket 1 (post-sided)

- Check piston stroke

- Mount bracket 1 (post-sided)

- Position and mount bracket 2 on the gate

- Insert and tighten garden gate closer

Step 1: Determine mounting position of garden gate closer

First, you need to determine the position of the gate closer. It can be positioned at the top of the gate, in the middle or at the bottom. It is important that it is mounted levelled! As well, the two brackets (bracket 1 and bracket 2) need to find sufficient hold on the wall and on the gate respectively. The larger bracket (bracket 1) is to be mounted on the post. The smaller bracket (bracket 2) is to be mounted on the gate.

Step 2: Measure bracket 1 (post-sided)

After having positioned the gate closer correctly, check the distance of the gate´s pivot point (located in the middle of the hinges) and the pivot point of the closer (chosen mounting hole of bracket 1). For measuring use the larger bracket (bracket 1).

The sum of the two distances A and B should not exceed 150 mm, and also should not be less than 140 mm either. However, if the sum of the distances is bigger than 150 mm, the gate can only be opened a little less than 90° at worst.

The pictures below show an example in which the distance A is about 65 mm. That means the distance from the centre of the hinges to, in this example, the inner mounting hole of the larger bracket 1. Now move bracket 1 laterally alongside the post until distance B is 85 mm. Just as done when measuring distance A, distance B is also defined by measuring from the centre of the hinges to the position of the mounting hole on the bracket.

Note: In step 3 the exact positioning of the bracket will be checked again and possibly fine-tuned.

Step 3: Check piston stroke

This step is to check the measured position of bracket 1 and possibly change it slightly, so that the optimized closing performance can be guaranteed. If you choose to proceed with the measurements done before you can skip this step. However, we strongly advise you to take your time for this verification.

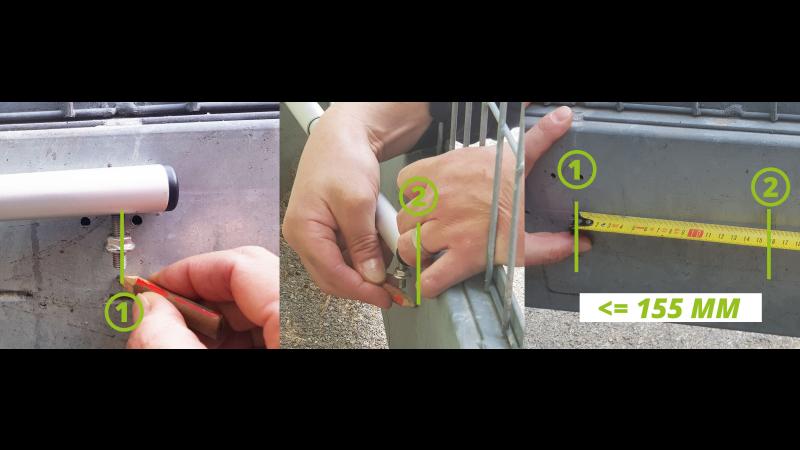

To verify the mounting positions fix bracket 1 provisionally at the position as measured before and install the gate closer in the mounting hole as chosen before. Close the gate and mark the position of the bolt on the frame of the gate (mark 1). Then open the gate and mark again the position of the bolt on the frame (mark 2).

If the distance between the two marks amounts to about 155 mm, the position of the bracket is optimal. If the distance is a bit less, increase distance B a bit. If the distance is bigger than 155 mm, decrease distance B or choose another mounting hole.

Note: The gate closer can be installed in any mounting hole of the bracket, as long as the distance is correct. If you use a larger bracket than 60 mm (90 or 120 mm) we advise you to choose one of the centred mounting holes so you can possibly fine-tune the gate closer later.

Step 4: Mount bracket 1 post-sided

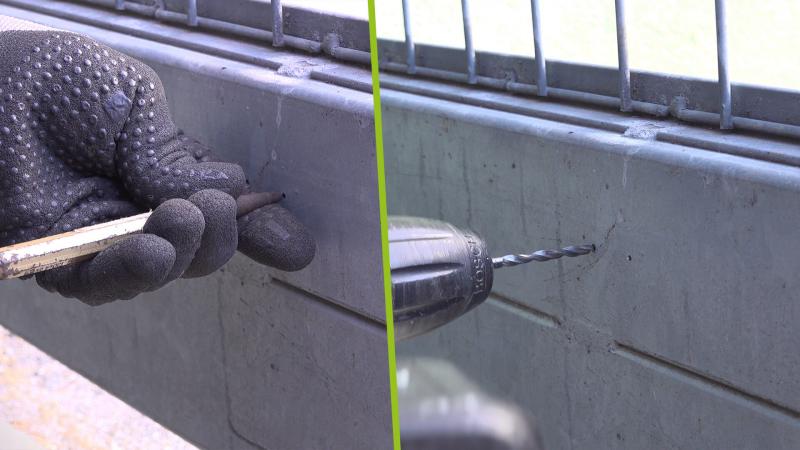

After having found the correct position of bracket 1, mark the drilling holes with a pen. We recommend to centre-punch the drilling holes in order to prevent the metal drill from slipping off.

Drill the holes using a cordless screwdriver with a 4.2 mm drill. The drill’s dimensions are essential here because if using a smaller diameter, the screw can tear off. Using a bigger diameter, the screw doesn´t find sufficient hold.

After drilling, mount the bracket and tighten it using the tapping screws.

Step 5: Position and mount bracket 2 on the gate

Having positioned and fixed the first bracket (bracket 1) correctly, you´ve already done the biggest part of the mounting!

Now, the second bracket (bracket 2) must be positioned correctly on the gate. Therefore, the distance between the two mounting holes (that is the chosen mounting hole on bracket 1 and the mounting hole on bracket 2) must be between 540 mm and 545 mm. Exact measurement is essential here!

But be careful: If this distance is too small, the gate will only open a little less than 90°. If it is too big, the gate won´t close entirely.

Having measured the distance correctly, check the vertical position of the brackets using the spirit level!

Now, mark and centre-punch the drilling holes. Then drill the holes using a 4.2 mm metal drill. The size of the drill is essential here. If the diameter of the hole is too small, the screw can tear off. If it is too big, the screw won´t find the hold required. Fix bracket 2 with the tapping screws enclosed.

Attention: If you adjust the position of bracket 1 later, bracket 2 must be re-positioned as well to ensure the correct hole-to-hole distance.

Step 6: Insert and tighten garden gate closer

For easier mounting, the garden gate closer is pre-loaded when delivered. For inserting the gate closer, open the gate until the gate closer can be put into the respective holes without applying any force. The thicker end of the closer is to be put into bracket 1 (near the wall). The slimmer end is being inserted into bracket 2 (on the gate).

Finally, the gate closer is fixed using the cap nuts. Therefore screw on and tighten the cap nuts using the locknuts. In this step the nuts must be tightened in such a fashion, so that the threaded rods are straightened and stand in right angles to the mounting bracket.

Note: In most cases, the pre-loading security bolt loosens by itself during this procedure. In case that the bolt remains, carefully move the gate just a few millimetres towards its opening direction!

You’ve done it. We hope you enjoy your new Garden Gate Closer!

If you have any further questions about the assembly, do not hesitate to contact us via email office@gardengatecloser.com or via our WhatsApp service +43 664 881 89 781!

Your gardengatecloser.com team